VCI Bags: What They Are and How They Prevent Rust

- Freelancer Developer

- Jul 7, 2025

- 2 min read

Updated: Aug 13, 2025

When metal parts are exposed to moisture, oxygen, or even changes in temperature during storage or shipping, rust and corrosion become a real threat. That’s where VCI bags come in.

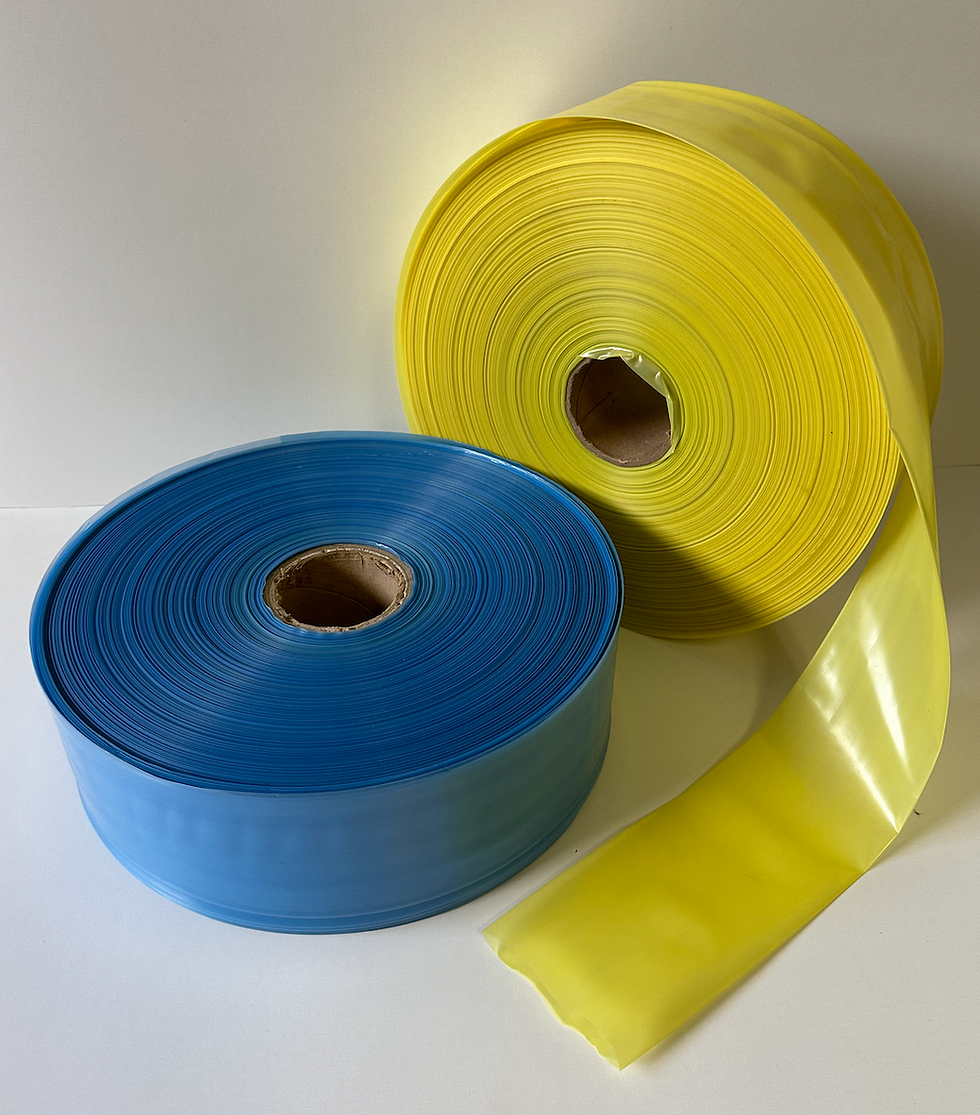

VCI stands for Vapor Corrosion Inhibitor — a specialized type of poly bag designed to protect metal components from rust without needing oils, coatings, or desiccants. At M Plastics, we manufacture custom LDPE bags using VCI additives to meet the needs of customers in automotive, aerospace, electronics, and other metal-sensitive industries.

What Is a VCI Bag?

A VCI bag is a polyethylene bag manufactured with corrosion-inhibiting chemicals blended directly into the resin. These additives release a safe, invisible vapor that forms a molecular shield on the surface of metal items stored inside the bag.

The result: clean, dry protection against corrosion for ferrous and non-ferrous metals, often without needing extra materials like paper wraps or anti-rust oils.

How VCI Technology Works

VCI additives are built into the LDPE during the extrusion process. When a metal item is sealed inside a VCI bag, the additive slowly vaporizes, creating a corrosion-inhibiting atmosphere inside the bag. This invisible vapor:

Bonds to the metal surface

Blocks moisture, salt, and oxygen from reacting with the metal

Does not interfere with surface treatments, coatings, or welding

Once the bag is removed, the vapor dissipates harmlessly — leaving the part clean and ready for use.

When and Where to Use VCI Bags

VCI bags are ideal for protecting metals during:

Export shipments (especially overseas)

Long-term storage of inventory

Military and defense equipment staging

Electronics or tool packaging

Metal components and machine parts

They are commonly used by:

Flat lay bags for small parts or kits

Side-gusseted bags for larger or bulkier items

Wicketed VCI bags for high-speed automated packing

Custom gauge, size, and print options available

Our VCI film is produced with in-line extrusion and converting, and we can provide spec sheets or lab results to verify performance.

Final Thoughts

Rust can ruin quality, slow down assembly, and cost companies thousands in lost parts and replacements. VCI bags offer an efficient, dry, and clean solution to protect metal goods throughout the supply chain.

Blown film manufacturers like M Plastics offer reliable VCI packaging options that integrate directly into your workflow — helping protect your product without slowing down your process.

Let me know when you're ready for Post 7: What Is Poly Tubing? Flexible Packaging on Demand.

Comments